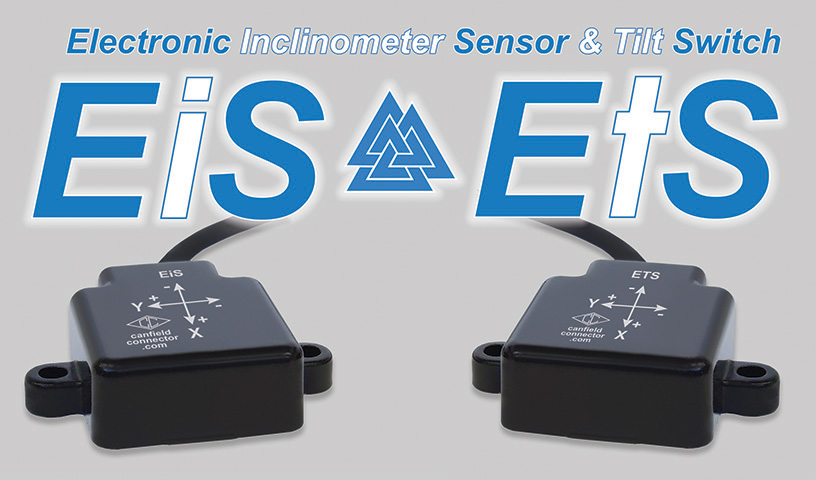

The Series EIS Inclinometer and Series ETS Tilt Switch provide efficient and accurate angle measurement in heavy equipment, mobile equipment, factory automation, construction, solar power and much more. Both products are essential to applications that require leveling, measuring, controlling, and adjusting of equipment and machinery for their optimal position. Some common applications for the EiS and ETS series include:

- Leveling mobile work platforms and prevention of overturning, falling or collision of mobile elevated work platforms

- Measuring and Adjusting the optimal angle for solar panels or measuring and adjusting the angle and height of drilling in well logging

- Controlling boom angle and boom height of automatic control sprayers in agriculture

- Measuring range of motion in the joints of the body